Understanding How to Handle Different Types of Freight

Choosing the correct freight class is essential when shipping finished goods, consumables, and commodities. This ensures that parcels, cartons, boxes, and pallets are properly stored, handled, loaded, and unloaded. More importantly, proper classification determines freight costs. Everything that ships by LTL must have a corresponding freight classification.

So, what are these freight classes, and who determines them?

The National Motor Freight Traffic Association

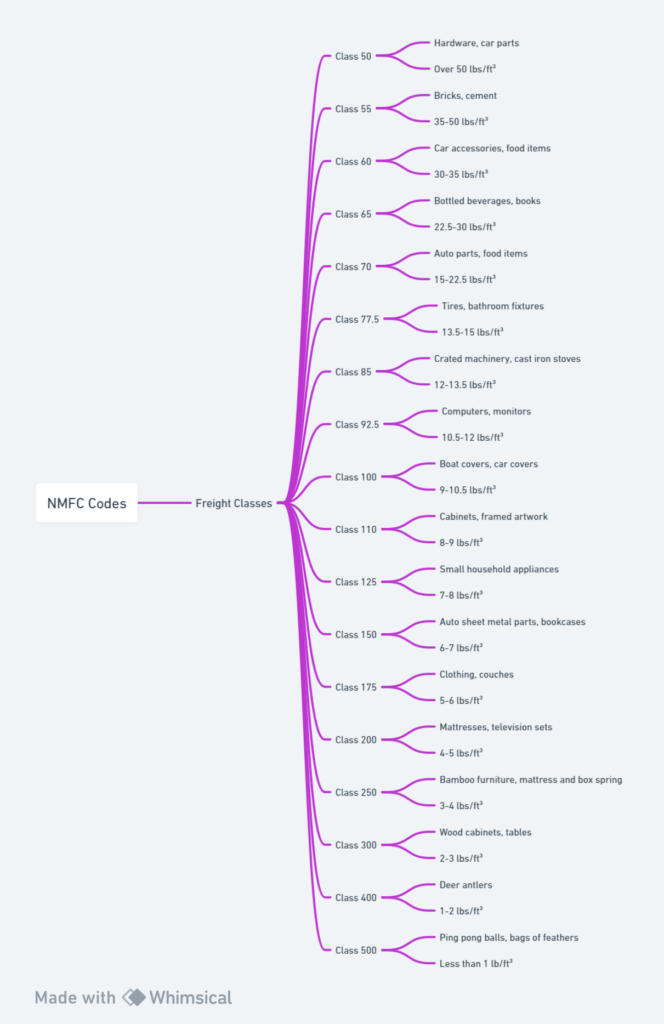

Freight classes are determined by the National Motor Freight Traffic Association (NMFTA). The NMFTA uses different criteria to determine a shipment’s National Motor Freight Classification (NMFC). There are 18 NMFC freight classes, each defining a different freight rate or transport cost.

Generally, the lower the freight class, the less expensive it is to transport. However, choosing a lower freight class to get better rates won’t work, as freight companies will re-classify the freight, which does nothing more than add unnecessary delays. That’s why it’s important to always be as accurate as possible with a shipment’s freight class.

Additionally, NMFC classes define freight carriers’ taxes, tariffs, shipping processes, and storage procedures. Each of these carriers will have their own set of rules and processes for different classifications, so new truck drivers should expect to be thoroughly trained in those processes.

Understanding NMFC Classification Criteria

The four criteria the NMFTA uses to classify NMFC freight include density, stowability, handling, and liability. Each is explained in detail below.

Density

The density and NMFC class tell a freight carrier how much physical space a shipment occupies within a trailer. A shipment’s density is calculated in pounds per cubic foot by dividing the weight by the cubic feet of the parcel or box the shipment is stored in. A higher density implies that the items within the parcel are more tightly packed and, therefore, denser and less susceptible to damage during transit. Shipments with higher density are assigned a lower NMFC class.

Stowability

Much like the name implies, a shipment’s stowability refers to how simple or easy it is to place it within a trailer. If the shipment is stored in a box, parcel, or square container, it is much easier to store than a shipment with non-uniform dimensions or an irregularly shaped item. The parcel that is easier to store and stow away would have a lower NMFC class and, generally, a lower cost.

Handling

Handling is defined by how easy it is to maneuver, push, move, lift, or adjust the shipment when loading and unloading it from a trailer. Large, irregularly shaped, and heavy shipments are more difficult to handle than lighter, uniform shipments. Shipments that are more difficult to handle would receive a higher NMFC class and, therefore, be more expensive. Fragile shipments that require more handling time and preparation would also have a higher NMFC class and price.

Liability

This criterion refers to the potential liability incurred by the LTL freight company when transporting certain types of freight. A shipment of highly flammable or hazardous material will have a high NMFC classification as opposed to a shipment that is less dangerous, less hazardous, or not flammable. A freight forwarder transporting chemicals, oils, gases, or other potentially dangerous material or flammable shipments must cover higher insurance costs in the event of road accidents, damage to the shipment or trailer, and spillage. They will also have to take additional precautions and steps to ensure the safety and protection of the drivers and the remaining freight within the trailer.

Handling Tips by Freight Type

Standard Cargo

Standard cargo coincides with a lower NMFC classification number, which means a lower cost. A perfect example is class 50 shipments, which are often referred to as clean freight. Class 50 shipments are registered as 50 pounds and higher per cubic foot. Class 50 items must be properly packaged, not susceptible to damage, and easily stored and transported on pallets.

Freight carriers will load class 50 items based on the type of trailer or trailer bed used in transit. Cab-over-engine trucks are rarely used in the United States, so most of the time, the pallets will be positioned over trailer’s rear axle.

Tips for Drivers:

- Store standard cargo on pallets.

- Ensure items are correctly tied to the pallets.

- Position pallets over the rear axle of the trailer.

- Ensure there is little movement between the pallets.

High-Value Items

High-value shipments will always have higher NMFC classification numbers due to the inherent value of the item or items being shipped. Class 500 items are considered the most valuable and are, therefore, more expensive to transport. Gold and other precious metals would be designed Class 500, as would antiques and items with high appraisals.

Depending on how many high-value items are being shipped, drivers should expect to go through various steps to ensure the shipment is properly secured, stored, and protected. In some cases, a third party may be responsible for loading the truck, and the drivers may be unable to witness the trailer being loaded or have to sign documentation attesting to specific delivery criteria.

Tip for Drivers:

- Follow the instructions given to you—every high-value shipment will be different. Some high-value shipments may require the truck driver to be fingerprinted or to provide an update at every stop.

Heavy or Bulk Items

Handling, storing, moving, loading, and unloading heavy or bulky items always presents an inherent risk. Always be mindful of the weight and size of heavy items. First, use push carts, battery-powered tugger carts, or forklifts whenever possible when moving or handling heavier loads. Second, never attempt to lift anything you know to be too heavy. You are not saving time. When lifting, always bend at the knees and never at the hips.

When loading a heavy parcel on a tractor-trailer, position the heaviest load in the center of the four axles with the remaining parcels or LTL shipments on the outer perimeter. Finally, always pre-plan how heavy loads are positioned within the trailer before starting your route.

Tips for Drivers:

- When moving heavy loads, use loading equipment, like push cards or forklifts.

- Get help lifting items when needed.

- Always bend at the knees and never at the hips.

- Place the heaviest load in the center of the four axles.

Hazardous Materials

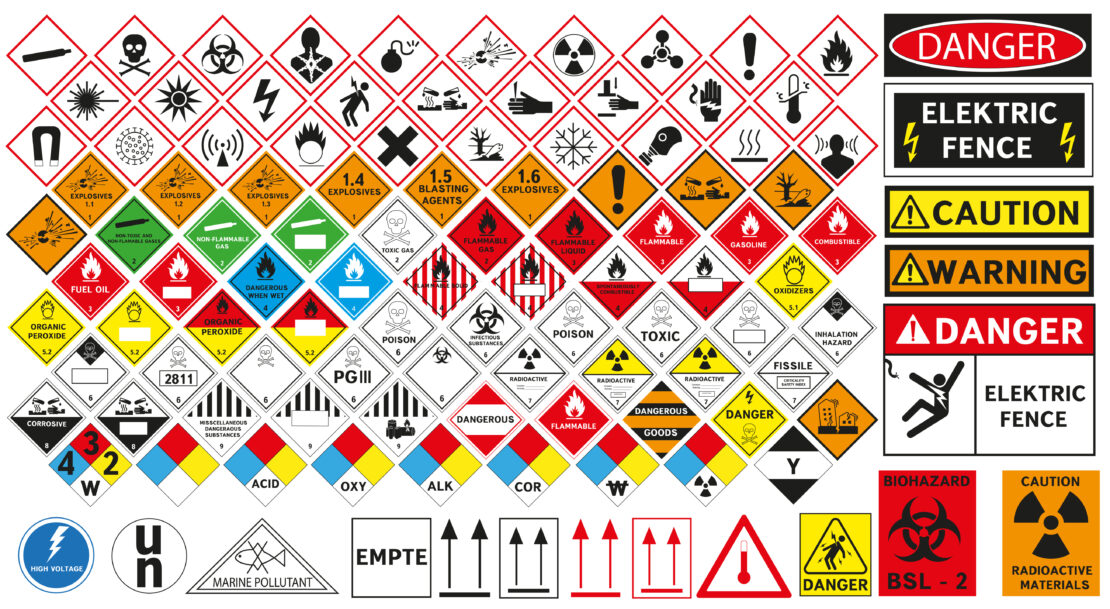

The Federal Motor Carrier Safety Administration (FMCSA), NMFTA, and the U.S. Department of Transportation (USDOT) regulate and mandate the shipping, handling, and classification of hazardous materials. The NMFC provides different codes for different types of hazardous materials, and each class defines its own set of procedures and processes for safe handling, storage, and transport.

NMFC Class 1 refers to explosives. Class 2 are gases. Class 3 consists of flammable liquids, while Class 4 consists of flammable solids. Class 5 refers to metals and other substances that can oxidize. Class 6 refers to toxic, hazardous materials and infectious particles, liquids, and substances. Class 7 is reserved for radioactive material. Class 8 is corrosive materials and substances, and Class 9 refers to all other hazardous materials that do not fit in the other categories.

Truck drivers must have a specific CDL endorsement to transport hazardous materials to ensure proper training on the various classes and handling requirements. Generally, all that’s required of truck drivers is correctly identifying the type (or types) of hazardous materials being shipped, safely loading the materials into the truck, and displaying the correct placard based on the classification of hazardous materials being shipped.

Tips for Drivers:

When loading hazardous materials onto trucks, drivers should:

- Ensure materials will not freely move around in the truck and are secure.

- Ensure materials are away from heat sources, including cargo heaters.

- Identify any leaks or damage to the shipment containers. Damaged or leaking containers should never be transported.

- Never smoke around flammables or explosives.

- Use fire- and water-resistant tarps for Class 1, Class 4, and Class 5 materials.

- Place Class 1, Class 4, and Class 5 materials in a closed cargo space.

Again, truck drivers will have to obtain a CDL H endorsement. Before taking the knowledge test, you will learn all of the necessary loading and handling requirements per hazardous materials class.

Fragile & Sensitive Items

Ultimately, when loading, packing, and unloading fragile and sensitive items, parcels, or boxes, the best approach is to inspect the parcel or box first to identify any critical labels or instructions. Most fragile shipments will be labeled as such or will, at the very least, have arrows indicating right-side-up placement.

Another source of important information will be found on the bill of lading. Properly filled-out documents like bills of lading will provide a breakdown of the contents of parcels and cargo. Ultimately, it’s on the packaging company that provides the parcels to ensure they’ve correctly identified or labeled cargo as fragile. Another factor would be if the parcel had high insurance coverage, as high insurance costs are often indicative of the inherent value of the shipment.

Tip for Drivers:

- Pay attention to and follow the instructions on the box.

Refrigerated & Temperature-Controlled Goods

Transporting refrigerated and temperature-controlled goods all comes down to having a fail-safe, error-proof contingency plan. Even the best-manufactured refrigeration equipment can fail. When it does, having a ready-made solution is always a good idea.

Drivers should always check and validate that the equipment is in good working order. A typical inspection involves checking thermostats, temperature sensors, and other cooling equipment while paying close attention to alarms or warning signs.

Additionally, drivers must limit how often doors are opened when in transit. Doors should only be opened when unloading or loading of cargo. Another critical tip is to ensure proper airflow throughout the container, as poor airflow can cause food and other refrigerated items to spoil. Air should be able to move between different cargo or freight within the refrigerated trailer. Using trailer chutes ensures proper airflow and a uniform temperature throughout the refrigerated trailer.

Tips for Drivers:

- Check refrigeration equipment before departing.

- Avoid frequent stops and only open doors when unloading or loading cargo.

- Ensuring proper airflow throughout the shipment container and truck trailer.

Learn More From TSI

TSI is a trusted long-haul freight forwarder that operates multiple routes, hubs, and destinations throughout the United States, Canada, and Mexico. In addition to helping automotive companies transport sensitive/fragile, heavy, valuable, and hazardous materials, we take pride in being a valuable resource for new drivers.

We offer a six-week, hands-on learning program for new truck drivers and always offer new job opportunities. Visit our blog for more resources, or sign up for our training program.